We leverage our experience in textile science to deliver purpose-driven, open-house collaboration with a focus on durability and low-impact raw materials and processes.

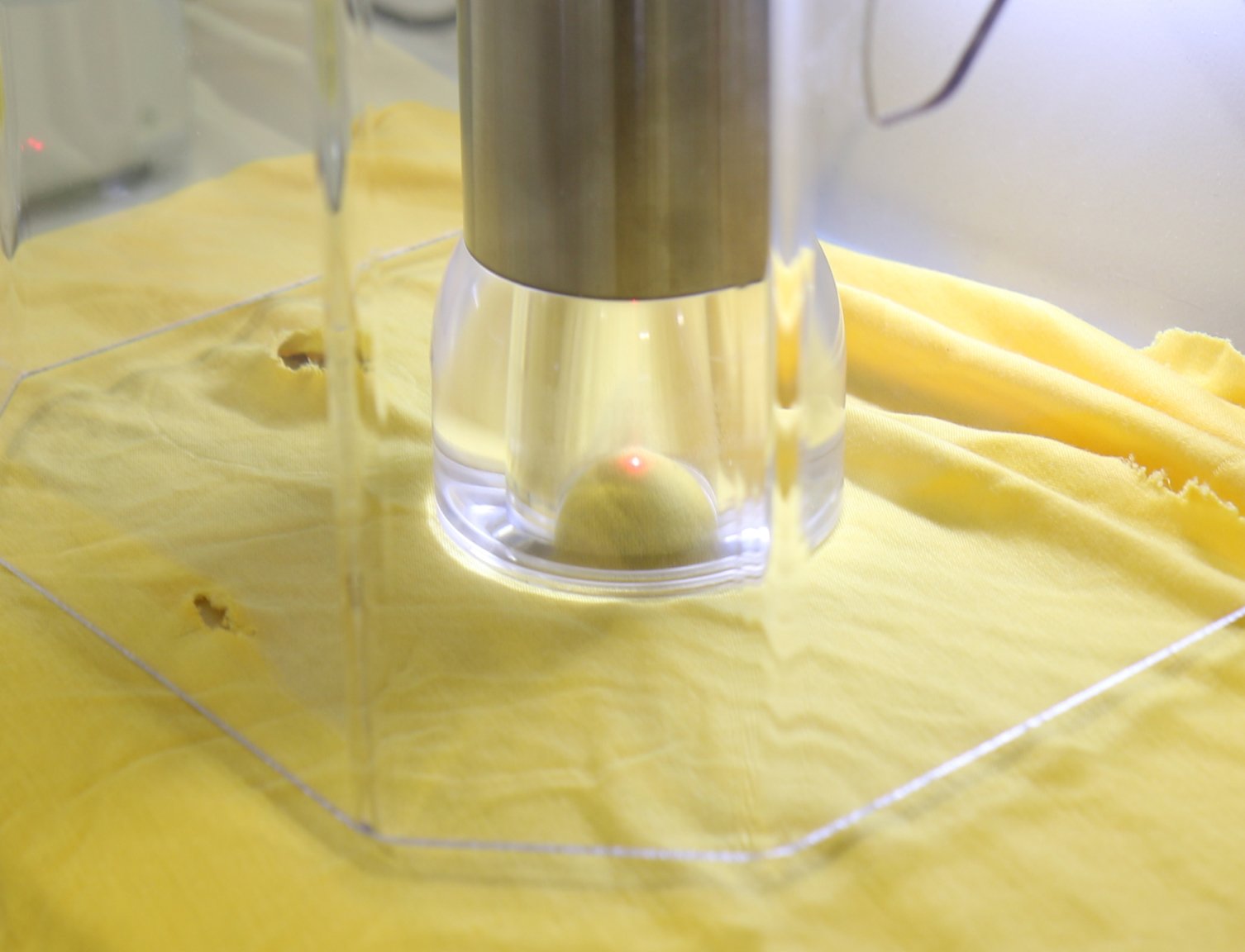

AI Technology for Quality Control Assurance

High Resolution Cameras

The world’s best inspector powered by AI & ML, CORE's cameras & sensors inspect fabric in real-time, spotting defects & irregularities.

Advanced Light Analysis

Smartex’s light system detects defects which are invisible to the human eye.

In 2020, we partnered with Portugal based textile innovation company Smartex to implement their CORE technology for realtime fabric inspection.

Product Development Strategy and Impact Goals — Driven by data

We have a world class textile laboratory in-house that allows us to examine and test products against R&D framework that is guided by science and results. By leveraging the capabilities of our onsite laboratory and team expertise, Casa da Malha can develop premium circular knits that are built for durability.

Testing

Pilling

Abrasion

Perspiration

Color Fastness

Twist Test

Friction

Humidity

Resistance

Dryer

Micro-Macro Microscopic

Light Chamber

Preferred Raw Materials Strategy

Plant Fibers

60% of Production

Organic cotton is grown without using pesticides and synthetic fertilisers. Our organic cotton is GOTS certified and sourced responsibly with ethical suppliers.

Organic Cotton

We’ve partnered with a small farms to bring cotton to the market that is grown using regenerative farming practices, with the goal to create regenerative impacts to the land. Good Earth Cotton™ is one of premiere regenerative cotton partners.

Regenerative Cotton

Recycled cotton is the lowest impact form of cotton on the market. Refined from textile waste, the natural fiber characteristics of the cotton are kept intact, the way nature engineered it.

Recycled Cotton

Kapok is a natural cellulose plant fiber obtained from the fruit of the kapok tree, or the tree itself. Kapok fibre is a non-food fruit crop which can be picked, like an apple, from the tree on which it grows - leaving the tree to grow and prosper. Kapok trees need no irrigation, no pesticides, and no fertilisers. They can grow on hills, in a biodiverse environment, and on land which is not suitable for agricultural purposes - resulting in 100% positive impact on the environment.

Kapok

Flax/linen is a natural plant fibre that uses low-impact production methods: grown on rotation, it is an eco-friendly crop that requires no irrigation, no defoliants and is GMO-free. The transformation process from plant to fibre requires no additional water and all parts of the plant are valued.

Linen

Like its cousin, fax, hemp is a “bast” fiber, which means that the fiber-producing part of the plant is made up of strands that run its length and surround the woody core of the stem. It grows quickly, is naturally resistant to many insect species, and needs little water to cultivate. It also has a deep root system, which helps to reduce soil loss and erosion, and is useful in many different crop rotations.

Hemp

Animal Fibers

5% of Production

Wool is possibly the oldest fiber known to humans. It was one of the first fibers to be spun into yarn and woven into the fabric. Of the major apparel fibres, wool is the most reusable and recyclable fibre on the planet. The eco-credentials of wool are enhanced by its long service life and suitability to be recycled into new textiles for clothing.

Wool

Cashmere is a natural protein fiber that comes from the Cashmere goat (the capra hircus langier). Quality is determined by fiber length, fiber fineness, and color. Cashmere goats grow two coats: a course outer coat and soft, fine inner coat that acts as extra insulation during winter.

Cashmere

Silk is a natural protein fiber produced by the larvae of a moth. It is the only natural filament fiber, one filament from one cocoon can measure 1000 yards! Generally speaking, silk is considered a more sustainable fiber. It is a renewable resource, can biodegrade, and uses less water, chemicals, and energy than many other fibers.

Silk

Man-Made

Cellulosic Fibers

20% of Production

Known for their natural comfort, TENCEL™ Lyocell fibers are produced in a closed loop process which recovers water and 99.8% of the solvent, which transforms wood pulp into cellulosic fibers with high resource efficiency and low environmental impact.

TENCEL™ Lyocell

Derived from certified renewable wood sources using an eco-responsible production process by meeting high environmental standards, LENZING™ ECOVERO™ fibers tailor to a sustainable lifestyle.

LENZING™ ECOVERO™ Viscose

A Next Generation material made by recovering cellulose from worn-out clothes and production scraps. Brands choose CIRCULOSE® as it replaces the use of virgin materials such as wood pulp or cotton, is available at scale through the CIRCULOSE® Supplier Network, and helps to close the loop on textile production.

Circulose®

Sourced from the ocean and harvested in fjords using sustainable practices: The fiber innovation SEACELL is a cellulose fiber, enriched with brown seaweed. The seaweed releases antioxidants and vitamins, which leads to a nourishing and revitalizing effect on the skin.

Seacell™

Orange Fiber is the world’s first brand to produce sustainable fabrics from citrus juice by-products. The innovative process has been patented since 2014 in the main citrus juice producing countries all over the world.

Orange Fiber

Synthetic Fibers

15% of Production

Polyester is one of the most versatile synthetic textile fiber on the market. We use a variety of specialty polyester fibers in additional conventional polyester including recycled polyester and biodegradable polyester.

Polyester

Polyamide, also known as nylon, is extremely durable, long-lasting with superior abrasion resistance and excellent thermal properties. In addition to conventional polyamide, we also use recycled polyamide and biodegradable polyamide.

Polyamide

Made from bio-renewable materials, NOOSA™ fiber is 100% recyclable thanks to a patented technology, NOOCYCLE™. The NOOSA™ fiber regenerates old textiles into a virgin fiber over and over again, providing a way for the textile industry to move towards a socially and environmentally responsible circular model. NOOSA™ proposes fibers and yarns to brands and manufacturers who then transform them into finished products. At the end of the product’s life cycle, the finished goods are re-collected and recycled in their entirety into a quality virgin fiber.

NOOSA™ PLA

Hyosung’s Creora® bio-based spandex is made by replacing 30 percent of petroleum-based resources with bio-based raw materials derived from industrial field corn, which is also called dent corn. According to a recent third-party life cycle assessment (LCA), the manufacture of Creora® bio-based spandex reduces its carbon footprint by 20% as compared to the production of regular spandex.

Creora®

We also work with

Conventional Cotton, Long Staple Cotton, Baby Camel, Bamboo / Aloe Vera, Viscose, Soy Bean, Nettle, Banana, Pineapple, and others.